Brake calipers are an essential component of a vehicle’s braking system. They are responsible for applying the necessary pressure to the brake pads, which then press against the rotor to slow down or stop the vehicle. There are two main types of brake calipers: floating and fixed. Floating calipers move in and out relative to the rotor, while fixed calipers remain stationary. Both types work in a similar manner, using hydraulic pressure from the brake fluid to engage the brake pads.

Brake calipers are typically made of cast iron or aluminum and contain pistons that push the brake pads against the rotor. When the brake pedal is pressed, hydraulic pressure is applied to the caliper, causing the pistons to move and apply pressure to the brake pads. This friction between the pads and the rotor is what ultimately slows down or stops the vehicle. It’s important to regularly inspect and maintain brake calipers to ensure they are functioning properly and to prevent any potential safety hazards on the road.

Key Takeaways

- Brake calipers are essential components of a vehicle’s braking system, responsible for applying pressure to the brake pads and slowing down the vehicle.

- Proper brake caliper compression is crucial for ensuring efficient and safe braking performance, as it allows the brake pads to make full contact with the rotor.

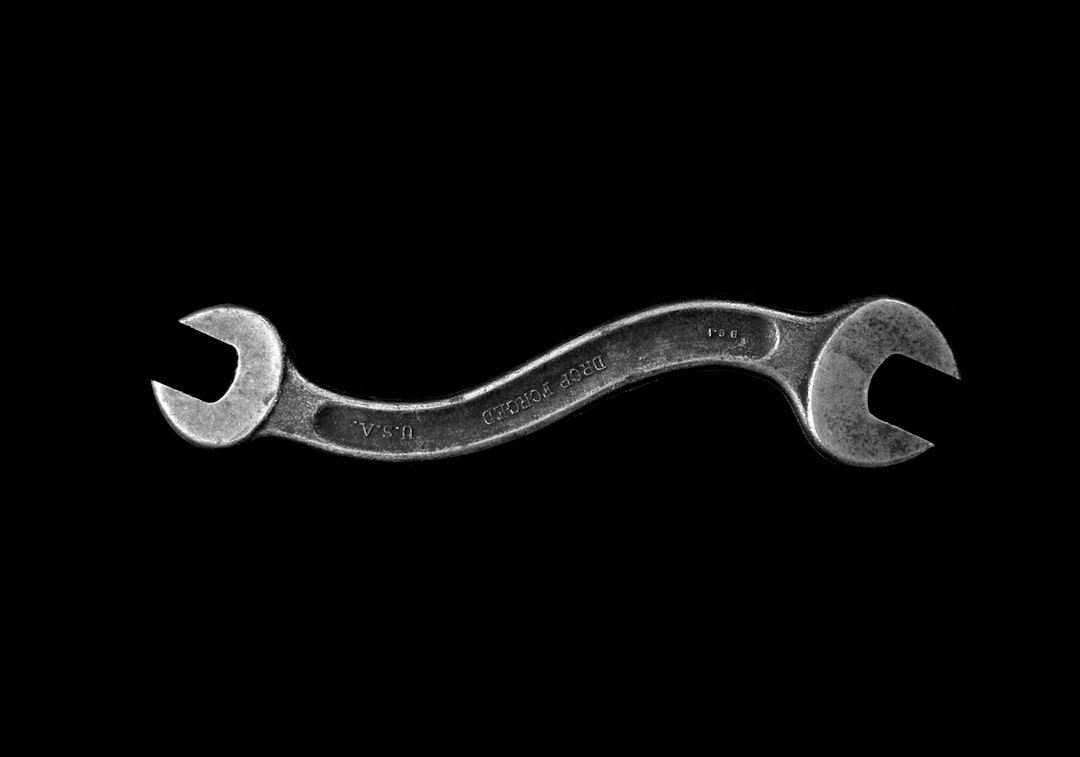

- Essential tools for brake caliper compression include a C-clamp or brake caliper compression tool, a wrench, and brake fluid.

- Mastering brake caliper compression involves following a step-by-step process, including removing the caliper, compressing the piston, and reassembling the caliper with new brake pads if necessary.

- Common mistakes to avoid during brake caliper compression include using the wrong tools, over-tightening the caliper bolts, and neglecting to properly bleed the brake system.

Importance of Brake Caliper Compression

Brake caliper compression is a crucial aspect of maintaining a vehicle’s braking system. When the brake pedal is pressed, hydraulic pressure is applied to the caliper, causing the pistons to move and apply pressure to the brake pads. Over time, air can get trapped in the brake lines, leading to a spongy or unresponsive brake pedal. This can result in decreased braking performance and potentially dangerous driving conditions.

Proper brake caliper compression ensures that the brake pads make full contact with the rotor, allowing for efficient braking and optimal vehicle control. It also helps to prevent uneven wear on the brake pads and rotor, extending the lifespan of these components. Regularly compressing the brake calipers also helps to maintain the overall performance and safety of the vehicle’s braking system.

Essential Tools for Brake Caliper Compression

When it comes to compressing brake calipers, having the right tools is essential for a successful and safe process. Some of the essential tools for brake caliper compression include a C-clamp or brake caliper compression tool, a set of wrenches or sockets, a torque wrench, brake fluid, and a container for old brake fluid disposal.

A C-clamp or brake caliper compression tool is used to push the caliper piston back into its housing, allowing for new brake pads to be installed. Wrenches or sockets are necessary for removing the caliper bolts and brackets, while a torque wrench ensures that these components are properly tightened to manufacturer specifications. Brake fluid is also essential for topping off the reservoir after compressing the calipers, and a container for old brake fluid disposal helps to keep the work area clean and environmentally friendly.

Step-by-Step Guide to Mastering Brake Caliper Compression

| Step | Description |

|---|---|

| 1 | Loosen the lug nuts on the wheel |

| 2 | Lift the car and remove the wheel |

| 3 | Remove the caliper bolts |

| 4 | Compress the caliper piston using a C-clamp |

| 5 | Install new brake pads |

| 6 | Reinstall the caliper and tighten the bolts |

| 7 | Put the wheel back on and lower the car |

| 8 | Tighten the lug nuts and test the brakes |

1. Prepare the vehicle: Park the vehicle on a flat surface and engage the parking brake. Loosen the lug nuts on the wheels and lift the vehicle with a jack, then remove the wheels to access the brake calipers.

2. Remove the caliper: Use a wrench or socket to remove the caliper bolts and brackets, then carefully remove the caliper from the rotor. Be sure to support the caliper with a wire or bungee cord to prevent damage to the brake line.

3. Compress the caliper: Place a C-clamp or brake caliper compression tool over the caliper piston and slowly tighten it to push the piston back into its housing. This allows for enough space to install new brake pads without damaging the caliper or brake line.

4. Inspect and clean: While the caliper is off, take the opportunity to inspect for any signs of damage or wear. Clean any debris or corrosion from the caliper and rotor using a wire brush or brake cleaner.

5. Reinstall the caliper: Once the new brake pads are installed, carefully reposition the caliper over the rotor and tighten the bolts and brackets to manufacturer specifications using a torque wrench.

6. Bleed the brakes: After compressing the calipers, it’s important to bleed the brakes to remove any air from the system. This ensures that the brakes are responsive and effective when driving.

Common Mistakes to Avoid

When compressing brake calipers, there are several common mistakes that should be avoided to ensure a safe and effective process. One common mistake is failing to properly support the caliper when it is removed from the rotor. This can put unnecessary strain on the brake line and cause damage to the system. It’s important to use a wire or bungee cord to support the caliper and prevent any potential damage.

Another common mistake is using excessive force when compressing the caliper piston. This can lead to damage to the piston or seal, resulting in brake fluid leaks and decreased braking performance. It’s important to use a C-clamp or compression tool and apply even pressure to slowly push the piston back into its housing.

Additionally, failing to properly bleed the brakes after compressing the calipers can result in air being trapped in the system, leading to spongy or unresponsive brakes. It’s important to follow proper bleeding procedures to ensure that the brakes are functioning at their best.

Tips for Maintaining Brake Calipers

Maintaining brake calipers is essential for ensuring optimal braking performance and overall vehicle safety. One important tip for maintaining brake calipers is to regularly inspect them for any signs of wear or damage. This includes checking for leaks, corrosion, or uneven wear on the brake pads and rotor. Catching these issues early can prevent more extensive damage and costly repairs down the line.

Another tip is to regularly clean and lubricate the caliper slide pins and bushings. This helps to ensure that the calipers move freely and evenly, allowing for consistent pressure on the brake pads. It also helps to prevent premature wear on these components, extending their lifespan.

It’s also important to use high-quality brake fluid and regularly flush and replace it according to manufacturer recommendations. This helps to prevent corrosion and contamination in the braking system, ensuring that it operates at its best.

Importance of Proper Brake Caliper Compression

Proper brake caliper compression is essential for maintaining a vehicle’s braking system and ensuring safe driving conditions. Understanding how brake calipers work and having the necessary tools and knowledge for compression is crucial for successful maintenance. By following a step-by-step guide and avoiding common mistakes, drivers can effectively compress their brake calipers and maintain optimal braking performance.

Regular maintenance and inspection of brake calipers, along with proper bleeding procedures, are key factors in maintaining a vehicle’s overall safety and performance. By following these tips and guidelines, drivers can ensure that their brake calipers are functioning at their best, providing reliable braking power when it’s needed most on the road.

If you’re looking for a high-quality brake caliper compression tool, you may also be interested in learning about the benefits of using foam in automotive manufacturing. Check out this article on auditfoam.com to discover how foam can improve the safety and performance of vehicles, including the components like brake calipers. Foam can provide cushioning and insulation for brake systems, helping to reduce noise and vibration while also enhancing overall durability.

FAQs

What is a brake caliper compression tool?

A brake caliper compression tool is a device used to compress the piston in a brake caliper when replacing brake pads or servicing the brake system.

Why do I need a brake caliper compression tool?

When replacing brake pads or servicing the brake system, the piston in the brake caliper needs to be compressed to make room for the new, thicker brake pads. A brake caliper compression tool makes this process easier and more efficient.

How does a brake caliper compression tool work?

A brake caliper compression tool typically features a threaded shaft and a handle. By turning the handle, the threaded shaft pushes against the piston in the brake caliper, gradually compressing it.

Can I use other tools to compress the brake caliper piston?

While it is possible to use other tools such as C-clamps or pliers to compress the brake caliper piston, a dedicated brake caliper compression tool is designed specifically for this task and can make the process easier and safer.

Are there different types of brake caliper compression tools?

Yes, there are different types of brake caliper compression tools available, including manual compression tools, pneumatic compression tools, and electric compression tools. The type of tool needed will depend on the specific requirements of the brake system being serviced.